LINE FOR PIPES INSULATION PTL-2A

The line is designed for initial drying of pipes, removal of mud, rust and friable scale from outer surfaces of steel pipes by round metal brushes and applying bitumen-rubber protecting coat-ings or protecting coating from adhesive polymeric tapes.

call us now : +7 (86138) 7-23-67

Technical characteristics

Work pipes diameter

Work pipes length

Line speed

Coating type

Manning level

Installed capacity (without auxiliary equipment)

Overall dimensions, width x length

57-426

10-36

1 700

normal and strong, from adhesive polymeric tapes

4

150

6 х 124

man

m per hour

kWt

m

m

Mass

45 000

kg

mm

The line is designed for initial drying of pipes, removal of mud, rust and friable scale from outer surfaces of steel pipes by round metal brushes and applying bitumen-rubber protecting coat-ings or protecting coating from adhesive polymeric tapes. Basically the line is intended for con-struction oil and gas fields, and also at laying of pipelines in trade and civil engineering.

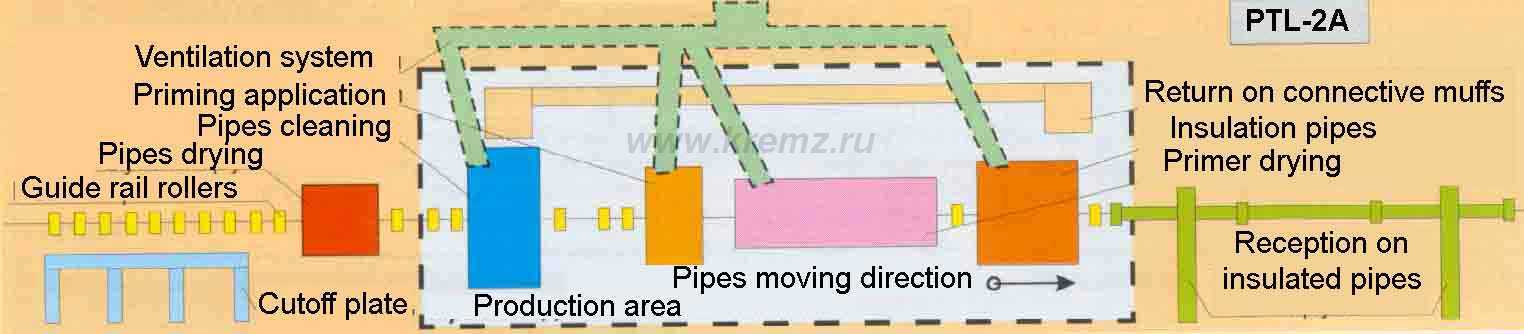

At the lower, there is PTL-2A line scheme in maximum completed. The technological layout of equipments is a single-line and stream-handling.

The PTL-2A line (completed) includes: device for pipes drying, cleaning machine, device for priming, camera for drying of the applied primer, device for insulating, device for receiving of the insulated pipes, driving and pressure supports, supports turning gear, device for the muffs return-ing, device for pipes loading, lift, cutting device, hydraulic system, ventilation system. In accor-dance with using insulation type and Customer order, the complete line can be changed.

The line must work in a complete with BK-31 bitumen melting boilers or vehicles for liquid bi-tumen delivery in the process of bitumen-rubber coating application. The line must be placed in a working area with no below 5 centigrade degrees above zero air temperature.

At the lower, there is PTL-2A line scheme in maximum completed. The technological layout of equipments is a single-line and stream-handling.

The PTL-2A line (completed) includes: device for pipes drying, cleaning machine, device for priming, camera for drying of the applied primer, device for insulating, device for receiving of the insulated pipes, driving and pressure supports, supports turning gear, device for the muffs return-ing, device for pipes loading, lift, cutting device, hydraulic system, ventilation system. In accor-dance with using insulation type and Customer order, the complete line can be changed.

The line must work in a complete with BK-31 bitumen melting boilers or vehicles for liquid bi-tumen delivery in the process of bitumen-rubber coating application. The line must be placed in a working area with no below 5 centigrade degrees above zero air temperature.

3, 3td Ptomyshlenny proezd, Kropotkin city, Krasnodar territory, Russia, 352387 (postal code)